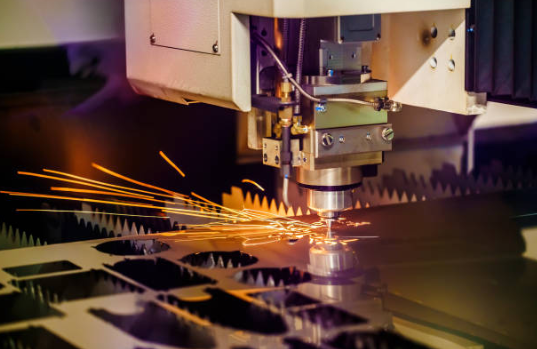

CNC laser cutting of sheet metal in modern industrial manufacturing

When it comes to the laser cutting of metal sheets, several factors directly influence overall cost. Each aspect, like the type and thickness of the material and the precision of the cut, plays a role in determining how much you’ll spend. In any case, calculating the cost of laser cutting is not just about numbers; it’s about understanding what drives those costs. So, whether you’re working with complex designs or simple cuts, knowing how to estimate the expenses can help you make informed decisions and avoid surprises down the line. In this guide, we’ll dive into the key factors that affect laser cutting costs and share tips on how to keep them in check.

Key Factors That Affect Laser Cutting Costs

When calculating the cost of laser cutting, several factors come into play. Understanding these elements helps you manage your budget effectively and make informed decisions. Let’s explore the key factors that influence the overall cost of laser cutting.

Material Type

The type of material you choose affects the cost. Different materials require different laser settings. Metals like stainless steel and aluminum are common but vary in how they absorb laser energy. For instance, cutting through stainless steel costs more than softer metals like aluminum. The material’s density contributes to how the laser interacts with it, directly influencing the price.

Another crucial factor is the thickness of the material. Thicker materials take longer to cut, increasing the machine’s operating time and energy consumption. As a result, cutting thicker metal sheets generally costs more than thinner ones. Thicker materials may also require more powerful lasers or multiple passes to achieve a clean cut, further driving up costs.

Machine Power and Efficiency

The power and efficiency of the laser cutting machine itself can influence costs. More powerful lasers cut through materials faster and more accurately, but they consume more energy. For instance, machines that offer faster cutting speeds can reduce the overall time spent on a project, potentially lowering costs. However, high-speed cuts might not be suitable for all materials or designs, especially if your project requires precision.

Machines with higher efficiency can cut costs by reducing energy consumption and shortening production times, but they also tend to be more expensive to operate. So it’s essential to consider the balance between power, efficiency, and cost.

Complexity of the Design

The complexity of your design has a direct impact on the cost. Simple cuts with straight lines are quicker and less expensive to execute. On the other hand, intricate designs with curves, holes, and detailed patterns require more time and precision. The more complex the design, the longer it takes to cut, which increases the cost. Intricate designs also require specialized software programming, adding to the overall expense.

Setup and Programming

Before cutting begins, a setup process includes programming the laser machine to execute the desired cuts. The time and effort required for this setup depend on the complexity of the design and the type of material intended for use. More complex setups require more programming time, which can add to the overall cost. If multiple designs or materials are involved, the setup costs can accumulate, making them a vital consideration in the budgeting process.

Quantity of Pieces

The number of pieces you need also affects the cost. Ordering a larger quantity often reduces the cost per unit because the setup and programming expenses are spread across more pieces. On the other hand, smaller batches might have higher costs per piece due to the fixed costs associated with setup and machine operation. High-volume production can lead to significant cost savings, especially when the design is consistent across all pieces.

How to Cut Down Laser Cutting Cost

laser cutting machine in operation

Reducing laser cutting costs doesn’t have to be complicated. With some smart strategies, you can manage your budget effectively without compromising quality. Let’s go through some practical tips to help you save money while still getting the desired results.

Optimize Your Design

The more straightforward the design, the less time it takes to cut, which reduces costs. So, try to minimize intricate details and avoid unnecessary complexity. Consider reducing intricate details, such as minor cuts, tight curves, and sharp angles. These features require more precision and time, which increases costs. Furthermore, using fewer cuts or combining multiple parts into a single cut can further optimize the design. Above all, simplification doesn’t mean compromising quality; it means being strategic about where to place details that matter most.

Choose the Right Material

Selecting the suitable material plays a crucial role in managing costs. Different materials vary in price, thickness, and cutting requirements. Metals like stainless steel, aluminum, and mild steel are common choices, but they have different properties that affect how they are cut. Stainless steel, for example, is more expensive and takes longer to cut due to its density and hardness. If your project doesn’t require the strength of stainless steel, opting for a softer and more affordable metal like aluminum can save money. Additionally, thinner materials are generally cheaper to cut because they require less power and time. By choosing a material that balances your needs with cost considerations, you can keep your project within budget.

Order in Bulk

If possible, order larger quantities of parts or pieces at once. Usually, bulk orders come with discounts, and the cost per unit decreases as you produce more pieces. This is because manufacturers will spend less time and money on programming, reducing the overall cost per piece. This is especially true if the design remains consistent across all units, as setup costs are spread out over a larger number of items. While it might require a larger upfront investment, bulk ordering can lead to substantial savings in the long run.

Work with Experienced Providers

Partnering with an experienced laser cutting service provider can make a big difference in cost management. Experienced providers know the ins and outs of laser cutting and can optimize the process to save time and money. They can advise on the best materials and designs to use for cost-effective cutting and help you avoid pitfalls that can drive up costs.

For instance, an experienced provider might suggest minor adjustments to your design that could reduce the number of cuts needed or recommend a different material that performs better and costs less. While it might be tempting to choose the cheapest provider, the long-term benefits of working with a knowledgeable and reliable partner often outweigh the initial savings from going with a less experienced option.

Consider Post-Processing Needs

Post-processing, such as cleaning, deburring, or finishing the cut pieces, can add to your overall cost. To reduce these expenses, choose materials and designs that require minimal post-processing. For instance, selecting a material that doesn’t produce much slag or residue during cutting can reduce the need for extensive cleaning afterward.

Similarly, designing parts with smooth edges can eliminate the need for additional finishing steps. This can reduce labor costs and speed up the production timeline. Working with a provider that offers in-house post-processing services can be more cost-effective than outsourcing these tasks to a separate company.

Conclusion

Bringing down laser cutting costs entails working smarter. Simplifying your design, choosing the right materials, and leveraging bulk orders are practical steps that significantly impact your budget. Planning efficiently and collaborating with experienced providers can further streamline your process, reducing waste and maximizing efficiency. These strategies, when combined, offer a balanced approach to managing expenses, allowing you to achieve precision and quality without breaking the bank.

At Zintilon, we’re committed to delivering top-notch laser metal cutting services at affordable rates. Our expert team is ready to bring your vision to life precisely and efficiently. So choose Zintilon for your laser metal cutting needs and watch your ideas take shape with unmatched quality. Get in touch with us now!

Leave a Reply